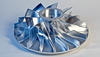

CAM Software for Turbomachinery components

Compressors, Pumps, and Turbines

Compressors, Pumps, and Turbines provide highly efficient service in many areas, from power generators to chemical processing to the jet engines found on airplanes. The demand for maximum efficiency begins in the production of the complex rotational parts used in them.

This includes impellers and blisks installed in turbomachines. Individual turbine blades are high-end components that have to meet many different requirements with regard to surface quality and profile accuracy. 5-axis milling processes are commonly used in the production of impellers and blisks.

Industry Challenges

-

Complex workpiece geometries

Reliable 5-axis strategies are necessary for machining highly complex impeller and blisk geometries

-

Materials that are difficult to machine

Innovative special strategies are required for the efficient and tool-friendly machining of titanium and Inconel

-

High surface quality and tight dimensional tolerances

Highly efficient strategies are necessary to achieve the required surface quality for impellers, blisks, and turbine blades with minimal programming

Programming made easy thanks to special packages perfectly matched to the requirements

The machining of impellers and blisks places high demands on CAM software. Standard 5-axis strategies are not sufficient for efficient NC programs used to produce these components. With its multi-blade package that targets impeller, blisk and turbine components, OPEN MIND is therefore able to offer machining strategies specially designed for simple and efficient programming of turbomachinery components. Integration into the familiar hyperMILL® environment enables other machining options to be combined and thus optimize or complete the production of parts. Other components such as diffusers and casings can also be programmed in a single software solution. The hyperMILL® special packages provide easy-to-use automated functions, allowing users to program even complex components without any specialized knowledge.

Would you like to learn more about our complete CAM solution for Turbomachinery components?

If so, please contact OPEN MIND Technologies.

CAM Strategies for Industry-specific Components

Multiblade

Singleblade

Automation speeds up programming

Like all other companies, turbomachinery manufacturers are also facing the constant need to cut costs. This makes it all the more important to design the end-to-end manufacturing process – from NC programming to milling – to be as economical as possible.

Feature and macro technology allow the user to save considerable time during NC programming. Having a simple definition of the key blade features enables the use of stored programming sequences in the form of a macro. The complete NC programming can thus be automated, standardized, and performed very quickly.

Leaving nothing to chance: simulation and collision avoidance

The simulation technologies and postprocessors developed by OPEN MIND allow even the most complex impellers, blisks, and turbine blades to be reliably manufactured every time. For instance, hyperMILL® VIRTUAL Machining offers an NC code-based simulation. This takes into account both the geometries and the kinematic behavior of all components involved in the manufacturing process. During simulated 5-axis machining, the user is shown the exact movements that the machine tool will actually perform. Integrated safety mechanisms ensure that only collision-free NC programs are transferred to the machine tool.

Videos: CAM software for Turbomachinery

Turbine Blade | GROB

This shows a machining example of a turbine blade on a GROB G550 machine programmed with CAM software hyperMILL®.

Advantages at a Glance

-

Integrated solution

Everything in a single user interface

-

Best-in-class 5-axis strategies

Enable safe machining of complex impellers, blisks, and turbine blades

-

Easy to program

Intuitive and supported by automated functions

-

High process reliability

Thanks to collision-checked toolpaths as well as reliable simulation and collision avoidance

-

Optimized roughing and finishing strategies

For efficient, tool- and machine-friendly machining, even when handling difficult-to-machine materials